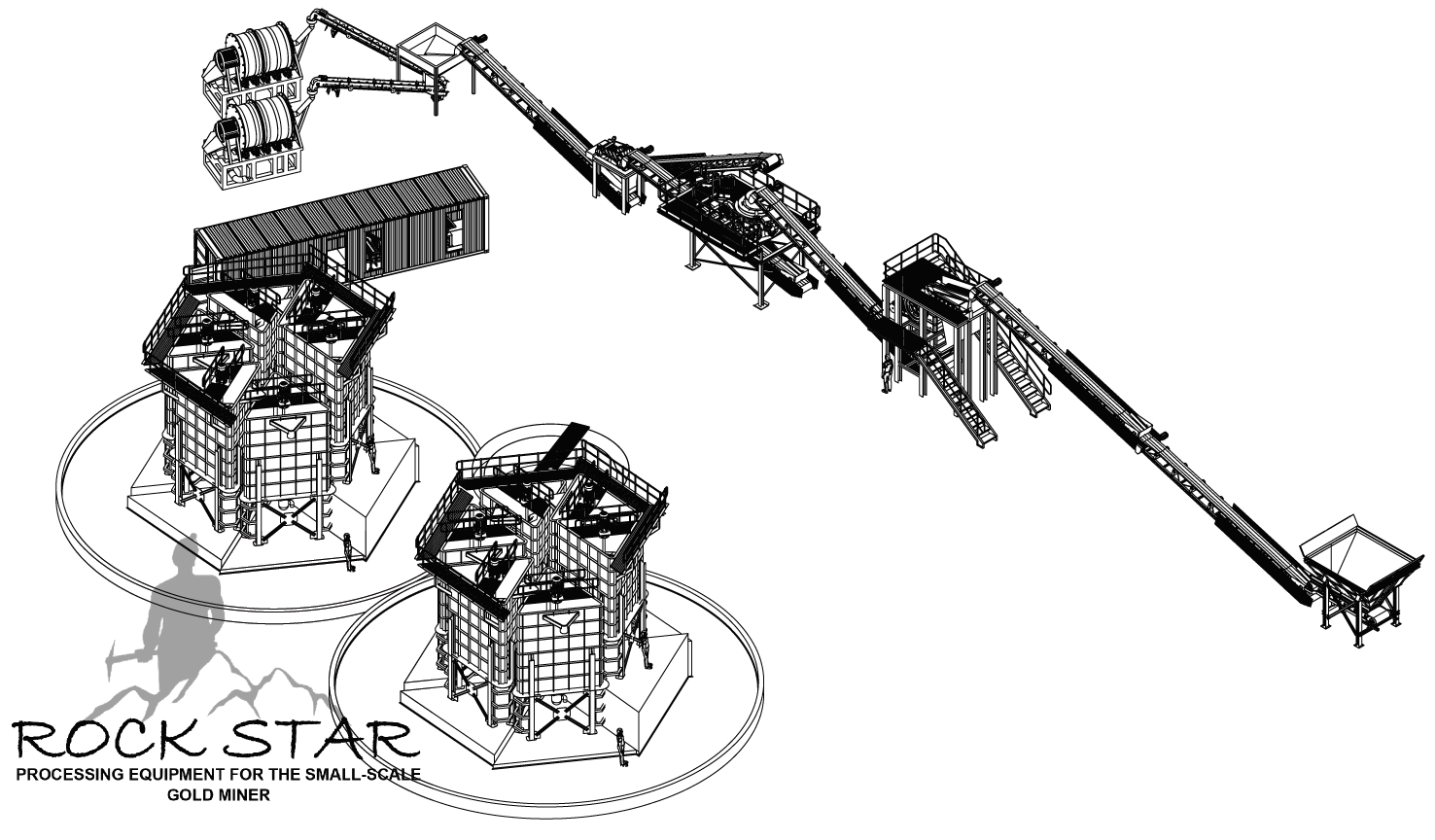

| General description: |

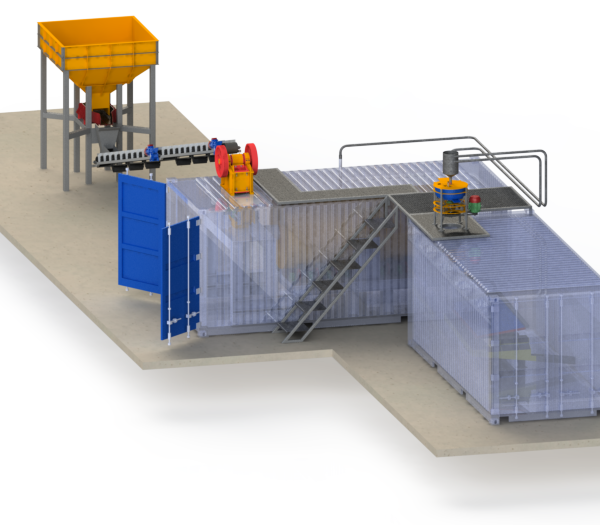

20 to 30 TPH medium scale gold operation complete with crushing, milling, gravity concentration, CIP leach plant and cleanout container / site office / store room |

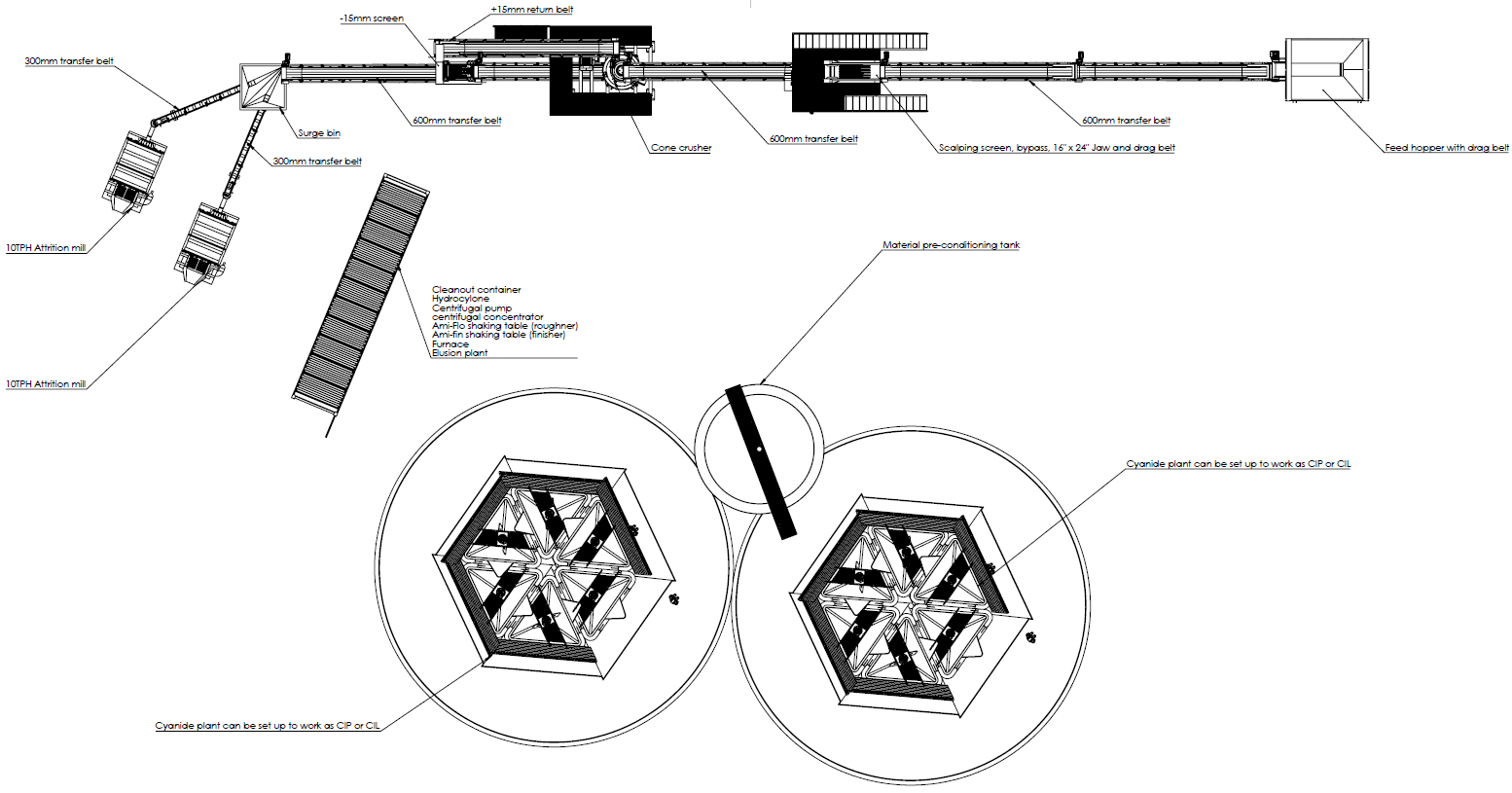

| Flow process: |

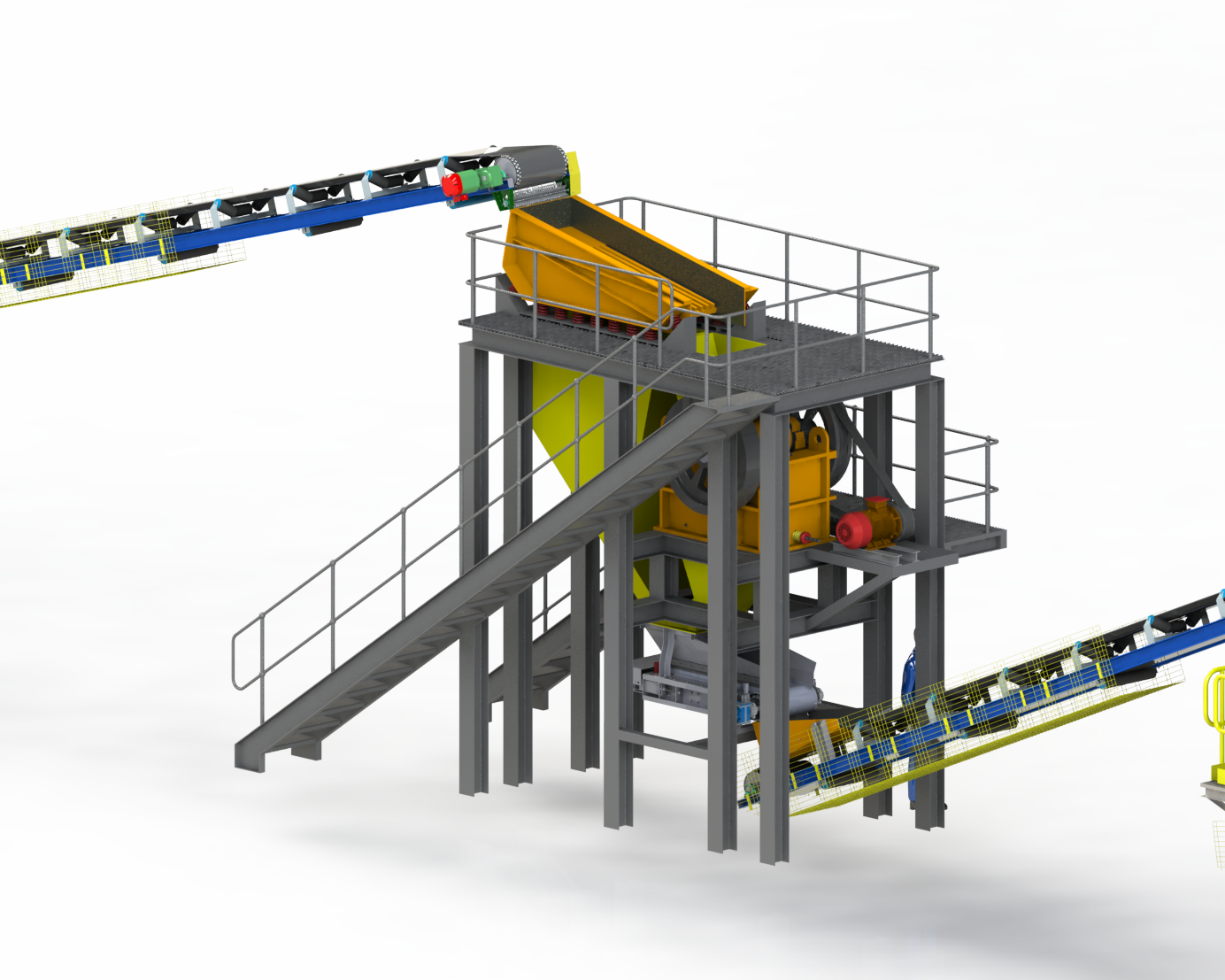

Feed hopper with drag belt |

| 30mm feed conveyor with side wall |

| 300mm x 200mm jaw crusher with ripped liners |

| 200mm transfer conveyor with side wall |

| Double roller mill |

| Attrition mill |

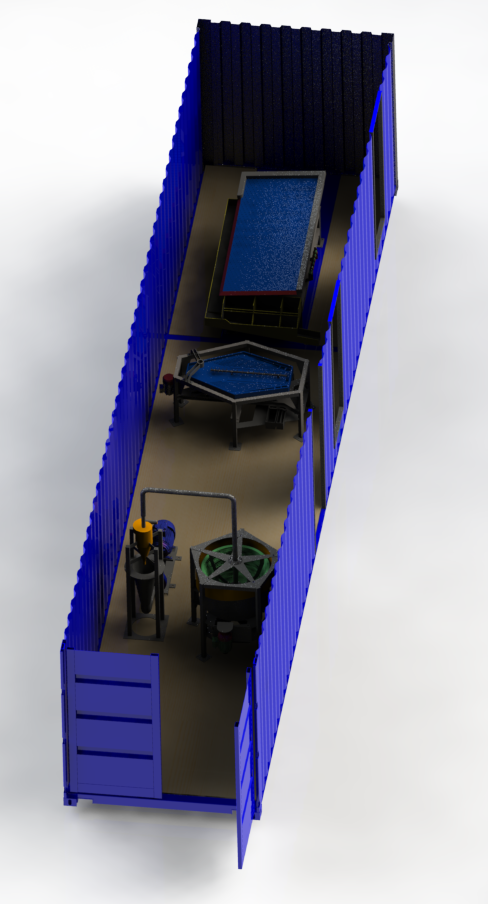

| 800mm centrifugal concentrator |

| Concentrates (Oxides) to Ami-Flo shaking table |

| Tailings (Sulphides) to stockpile |

| Stockpile and Oxides tailings to 1 TPH CIP leach plant |

| 3 x 1 foot vibrating carbon screen |

| Hoist with electrical drive, material basket and 100 m cable |

| Site office 2,4m x 2,4m wood with a corrugated steel roof and lockable door |

| Gas furnace, 2kg crushable and mould |

| Plastic portable toilet |

| 2 x 1.5″ centrifugal material pump |

| 1000 Lt water storage tank on stand |

| 1,8m x 200m chain link fence 4 x corner post, 40 x droppers, 3m gate and 2 x wire rolls |

| Tons per hour: |

20 to 30 TPH depending on the rock type |

| Transport dimensions: |

3 x 12m trucks |

| Working dimensions: |

20 long x 20 wide x 3,6 high |

| Power requirements: |

Running: 68Kw, 380VAC / Start-up: 85Kw, 380VAC (50 Hz) |

| Water requirements: |

(based on a SG of 1.8) 9,800 Lt water per hour |

| Water inlet: |

2″ / 50mm |

| Option extras not included: |

Water pump |

| Generator |

| Compressor |

| Compressor hose 1″ |

| Lay-flat or HDPE water pipe |

| 2 x Jack hammers |

| Civil work and commissioning |

| Generator |